Any unauthorized copying, reproduction, modification, or distribution of any part of this content is strictly prohibited without written permission from Newtech Insulation Company Limited. Any violation will be prosecuted to the fullest extent of the law.

Problems and Causes

Plastic injection machines are essential tools for polymer molding across nearly all industries. However, this factory faced uncontrollable electricity costs from operating more than 30 injection molding machines, particularly their most common 650-ton machines with injection barrels measuring 250mm in diameter and 1500mm in length. These machines operate 24 hours a day for 26 days per month. Beyond the excessive electricity consumption from the injection machines, workers were also required to use fans for personal cooling while working in these areas.

Improvement Methods

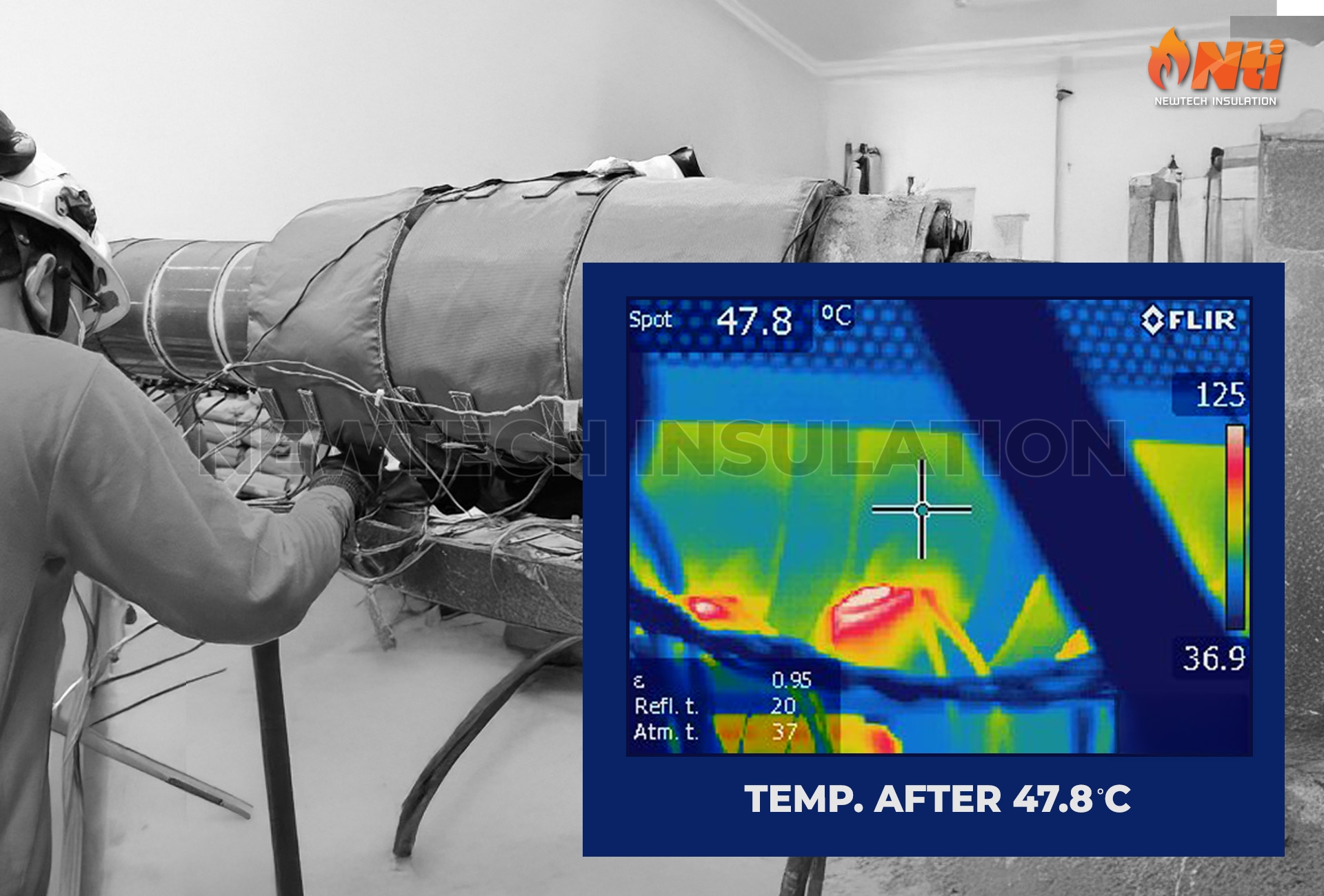

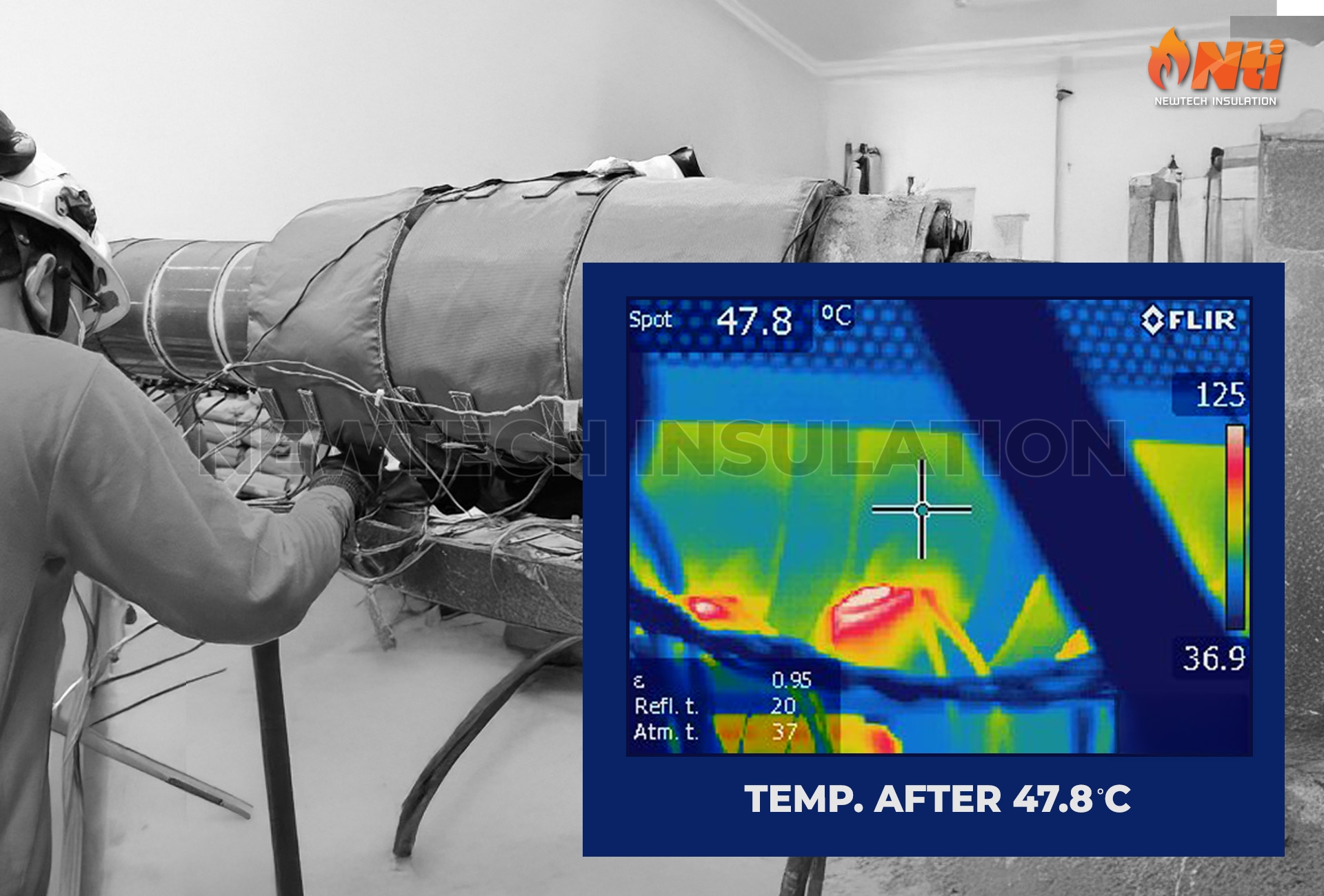

When collecting heat data during plastic injection machine operation, it was found that the machine surface temperature averaged 180-200 degrees Celsius, while the room temperature was approximately 37 degrees Celsius (in a non-air-conditioned space). With approximately 70mm of space between the injection machine surface and the metal safety guard, we recommended installing ZAVE® removable energy-saving insulation with a thickness of 50mm. This insulation has a Thermal Conductivity value of 0.06 W/m⋅K (watts per meter per kelvin) at 200 degrees Celsius. The removable insulation design allows for quick cleaning and maintenance of the injection barrel, with tool-free installation and removal.

Improvement Results

| Comparison Table: | Average Oven Surface Temperature (Celsius): | Annual Heat Loss (kW): | Annual Electricity Cost (Baht): |

| Before ZAVE® Insulation: | 200.0 | 28,572 | 100,848.00 |

| After ZAVE® Insulation: | 47.8 | 1,716 | 6,036.00 |

| Reduction: | 152.2 | 26,856 | 94,812.00 |